| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Surface Finishing | Polished |

| Shape | Rounded |

| Click to view more | |

Product Details

Level Switches: Guardians of Liquid and Bulk Material Levels

Level switches are essential components in various industrial processes and storage applications. They act as electronic or mechanical sentinels, monitoring the height of liquids or bulk solids in containers and triggering actions based on preset levels. Here's a breakdown of level switches, their types, and specifications to consider:

Function:

· Detect when a liquid or bulk material reaches a specific level within a tank, silo, or bin.

· Generate an electrical signal (on/off or analog) based on the detected level.

· This signal can be used to control pumps, valves, alarms, or other equipment to maintain desired fill levels, prevent overflows, or initiate refilling processes.

Types of Level Switches:

The choice of level switch depends on the type of material being monitored (liquid or solid) and the desired functionality. Here are some common types:

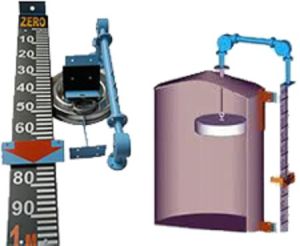

· Float Level Switches:

o A simple and reliable option for liquids.

o A buoyant float rises or falls with the liquid level, triggering a switch mechanism at preset high or low points.

· Displacer Level Switches:

o A displacer element suspended in the liquid moves due to buoyancy changes.

o This movement is detected by a magnetic or mechanical linkage, activating the switch at specific levels.

· Conductivity Level Switches:

o For conductive liquids.

o Electrodes at set points detect conductivity when submerged, indicating the liquid level reaching that point. (Not suitable for non-conductive liquids like oil)

· Ultrasonic Level Switches:

o Emit ultrasonic sound pulses and measure the time it takes for the echo to return.

o This time difference translates to the distance to the material surface, indicating the level. (Suitable for liquids, slurries, and some solids)

· Optical Level Switches:

o Use light beams to detect the presence or absence of material at a specific point.

o Can be suitable for clear liquids or opaque solids depending on the technology (e.g., photoelectric, light reflection).

· Radio Frequency (RF) Admittance Level Switches:

o Emit high-frequency radio waves to sense the presence or absence of material.

o Can be effective for liquids, slurries, and some solids with varying dielectric properties.

· Vibrating Fork Level Switches:

o A tuning fork vibrates at a specific frequency.

o When the material contacts the fork and dampens the vibration, the switch detects the change and indicates a high level. (Suitable for liquids, slurries, and some solids)

· Magnetostrictive Level Switches:

o Utilize a sound wave traveling through a rod to measure the level.

o The presence of material affects the wave propagation, triggering the switch at specific points. (Suitable for liquids and some solids)

Specifications to Consider When Choosing a Level Switch:

· Material Type: Liquid or bulk solid (and its properties like viscosity, abrasiveness)?

· Level Detection Points: High level, low level, or multiple points?

· Operating Temperature and Pressure: Compatible with the tank environment?

· Wetted Materials: Materials the switch will be in contact with (compatibility)?

· Electrical Rating: Output voltage and current requirements for connected equipment.

· Enclosure Rating: NEMA rating for protection against dust, moisture, or hazardous locations.

· Desired Features: Alarm contacts, control relays, data logging capabilities?

Additional Considerations:

· Cost: Level switches range in price depending on complexity and features.

· Ease of Installation and Maintenance: Consider accessibility and cleaning requirements.

· Approvals: Ensure the switch meets any regulatory requirements for your application.

Looking for "Level Switches" ?

Explore More Products