Level

Leading Manufacturers, Exporters, Wholesaler of Side Mounted Magnetic Level Indicator, Float and Board Type Level Indicator, Guided Wave Radar Level Transmitter and Level Switches from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Color | Black |

| Condition | New |

| Automatic Grade | Automatic |

| Guage Shape | Round |

| Application | Testing Water Level |

| Feature | Accuracy, Easy To Fit, Measure Fast Reading, Perfect Strength |

| Display Type | Digital |

| Type | Magnetic Level Indicators |

| Country of Origin | India |

| Payment Terms | T/T |

| Packaging Details | Box |

Level indicators, unlike level switches, provide a continuous visual representation of the level of liquid or bulk solids within a container. They offer a more informative way to monitor fill levels compared to level switches that simply trigger an on/off signal at preset points. Here's a breakdown of level indicators and their various types:

Function:

· Provide a direct visual indication of the level of liquid or bulk material in a tank, bin, or silo.

· Allow for continuous monitoring of fill levels without relying solely on electrical signals.

· Can be used for various applications, including process monitoring, inventory control, and ensuring safety by preventing overfills.

Types of Level Indicators:

The choice of level indicator depends on the type of material being monitored (liquid or solid) and the desired level of detail:

· Sight Glasses (Tubular Level Gauges):

o Simple and cost-effective option for liquids.

o Consists of a transparent tube or window mounted on the side of a tank, allowing you to see the liquid level directly.

o Suitable for various tank sizes and pressures depending on the material.

· Reflex Level Gauges:

o For liquids with different refractive indexes (light bending properties) than the gauge material.

o The interface between the liquid and empty space appears as a distinct line due to refraction, indicating the level.

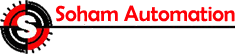

· Magnetic Level Indicators:

o Utilize a magnetic float inside the tank connected to an external indicator with red and white sections.

o The red section rises with the float as the liquid level increases, providing a visual indication. (May not be suitable for all liquids or environments with strong magnetic fields)

· Electronic Level Indicators:

o Employ electronic sensors and a digital display to show the liquid level.

o May use various sensing technologies like ultrasonic or radar and offer features like level scaling and data logging.

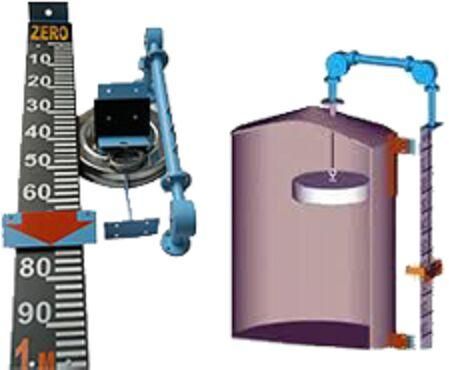

· Float and Board Level Indicators:

o Primarily for large tanks with bulk solids.

o A float rides on the surface of the material, connected by a cable and pulley system to an indicator board outside the tank.

o The board moves up or down to visually represent the fill level.

Additional Considerations When Choosing a Level Indicator:

· Material Type: Liquid or bulk solid (and its properties like transparency, viscosity)?

· Tank Material and Pressure: Compatible with the sight glass or enclosure material?

· Temperature Range: Suitable for the operating environment?

· Desired Level Detail: Basic level indication or need for precise measurements?

· Visibility Requirements: Viewing distance and ambient light conditions?

· Cost and Maintenance: Evaluate initial cost and ease of cleaning or maintenance.

Advantages of Level Indicators:

· Simple and Easy to Use: Provide a clear visual representation of fill levels.

· Reliable Operation: Generally less complex than level switches, offering reliable monitoring.

· Cost-Effective: Many options are affordable, especially for basic level indication.

Disadvantages of Level Indicators:

· Limited Data Output: Do not typically offer data logging or remote monitoring capabilities.

· Accuracy: May not be as precise as some electronic level switches for specific applications.

· Visibility Concerns: Viewing angles or ambient light can affect readability in some cases.

Overall, level indicators provide a valuable tool for visual monitoring of liquid or bulk solid levels in various applications. By considering the type of material, tank conditions, and desired level detail, you can choose the most appropriate level indicator for your needs. They offer a simple, reliable, and cost-effective way to keep an eye on your inventory and ensure safe operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Color | Black |

| Condition | New |

| Automatic Grade | Automatic |

| Guage Shape | Round |

| Feature | Accuracy, Measure Fast Reading, Perfect Strength |

| Display Type | Digital |

| Type | Level Indicator |

| Country of Origin | India |

| Packaging Details | Box |

Level indicators, unlike level switches, provide a continuous visual representation of the level of liquid or bulk solids within a container. They offer a more informative way to monitor fill levels compared to level switches that simply trigger an on/off signal at preset points. Here's a breakdown of level indicators and their various types:

Function:

· Provide a direct visual indication of the level of liquid or bulk material in a tank, bin, or silo.

· Allow for continuous monitoring of fill levels without relying solely on electrical signals.

· Can be used for various applications, including process monitoring, inventory control, and ensuring safety by preventing overfills.

Types of Level Indicators:

The choice of level indicator depends on the type of material being monitored (liquid or solid) and the desired level of detail:

· Sight Glasses (Tubular Level Gauges):

o Simple and cost-effective option for liquids.

o Consists of a transparent tube or window mounted on the side of a tank, allowing you to see the liquid level directly.

o Suitable for various tank sizes and pressures depending on the material.

· Reflex Level Gauges:

o For liquids with different refractive indexes (light bending properties) than the gauge material.

o The interface between the liquid and empty space appears as a distinct line due to refraction, indicating the level.

· Magnetic Level Indicators:

o Utilize a magnetic float inside the tank connected to an external indicator with red and white sections.

o The red section rises with the float as the liquid level increases, providing a visual indication. (May not be suitable for all liquids or environments with strong magnetic fields)

· Electronic Level Indicators:

o Employ electronic sensors and a digital display to show the liquid level.

o May use various sensing technologies like ultrasonic or radar and offer features like level scaling and data logging.

· Float and Board Level Indicators:

o Primarily for large tanks with bulk solids.

o A float rides on the surface of the material, connected by a cable and pulley system to an indicator board outside the tank.

o The board moves up or down to visually represent the fill level.

Additional Considerations When Choosing a Level Indicator:

· Material Type: Liquid or bulk solid (and its properties like transparency, viscosity)?

· Tank Material and Pressure: Compatible with the sight glass or enclosure material?

· Temperature Range: Suitable for the operating environment?

· Desired Level Detail: Basic level indication or need for precise measurements?

· Visibility Requirements: Viewing distance and ambient light conditions?

· Cost and Maintenance: Evaluate initial cost and ease of cleaning or maintenance.

Advantages of Level Indicators:

· Simple and Easy to Use: Provide a clear visual representation of fill levels.

· Reliable Operation: Generally less complex than level switches, offering reliable monitoring.

· Cost-Effective: Many options are affordable, especially for basic level indication.

Disadvantages of Level Indicators:

· Limited Data Output: Do not typically offer data logging or remote monitoring capabilities.

· Accuracy: May not be as precise as some electronic level switches for specific applications.

· Visibility Concerns: Viewing angles or ambient light can affect readability in some cases.

Overall, level indicators provide a valuable tool for visual monitoring of liquid or bulk solid levels in various applications. By considering the type of material, tank conditions, and desired level detail, you can choose the most appropriate level indicator for your needs. They offer a simple, reliable, and cost-effective way to keep an eye on your inventory and ensure safe operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Color | Blue, Gery |

| Application | For Liquid Measuring |

| Type | Radar Level Transmitter, Radar |

| Country of Origin | India |

| Payment Terms | T/T |

| Packaging Details | Box |

In the world of industrial process control, keeping an eye on liquid levels is crucial. Guided wave radar (GWR) level transmitters offer a reliable and accurate solution for continuous level measurement in various tanks and storage vessels. Here's a breakdown of how they work and their key benefits:

Function:

· Unlike pressure-based level sensors or float switches, GWR transmitters utilize high-frequency microwave pulses.

· These pulses travel down a metallic probe (waveguide) extending into the tank.

· When the pulse reaches the liquid surface, a portion of the energy reflects back up the probe to the transmitter.

Operating Principle:

· The transmitter measures the time it takes for the pulse to travel down the probe, reflect off the liquid, and return.

· Since the speed of the microwave pulse in the probe is known, the transmitter can calculate the distance to the liquid surface based on the travel time.

Key Benefits of GWR Transmitters:

· High Accuracy: GWR provides precise level measurement, unaffected by factors like pressure, temperature, or vapor in the tank.

· Non-Contact Measurement: The probe doesn't come in contact with the liquid, making it suitable for various liquids, including corrosive or viscous materials.

· Wide Range of Applications: GWR transmitters can be used for various tank sizes and shapes, making them versatile for diverse industrial applications.

· Minimal Maintenance: With no moving parts, GWR transmitters require minimal maintenance compared to mechanical level sensors.

· Suitable for Foaming Liquids: Unlike ultrasonic sensors, GWR can penetrate through foam, providing accurate readings even in tanks with foaming liquids.

Applications of GWR Transmitters:

· Chemical Industry: Measuring levels of various chemicals, slurries, and acids in storage tanks and reactors.

· Food and Beverage Production: Monitoring levels of liquids like syrups, oils, and milk in processing tanks.

· Oil and Gas Industry: Measuring levels of crude oil, refined products, and water in storage tanks.

· Water and Wastewater Treatment: Monitoring levels in water storage tanks, reservoirs, and clarifiers.

· Power Generation: Tracking levels of water and other fluids in boilers and cooling towers.

Choosing the Right GWR Transmitter:

Several factors need to be considered when selecting a GWR transmitter:

· Tank size and shape: Ensure the probe length is suitable for the tank depth.

· Liquid properties: Consider factors like viscosity, corrosiveness, and the presence of foam.

· Desired accuracy level: Choose a transmitter with the appropriate accuracy specifications for your application.

· Operating temperature and pressure: Ensure the transmitter is compatible with the tank environment.

· Material compatibility: Select a probe material resistant to the liquids being stored.

In Conclusion:

Guided wave radar level transmitters offer a reliable and accurate solution for continuous level measurement in various industrial applications. Their non-contact operation, high accuracy, and wide range of applications make them valuable tools for ensuring efficient and safe process control.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Surface Finishing | Polished |

| Shape | Rounded |

| Color | Grey |

| Design | Standard |

| Usage | General |

| Packaging Type | Box |

| Specialities | High Tensile, High Quality, Heat Resistance |

| Country of Origin | India |

| Payment Terms | T/T |

| Packaging Details | Box |

Level Switches: Guardians of Liquid and Bulk Material Levels

Level switches are essential components in various industrial processes and storage applications. They act as electronic or mechanical sentinels, monitoring the height of liquids or bulk solids in containers and triggering actions based on preset levels. Here's a breakdown of level switches, their types, and specifications to consider:

Function:

· Detect when a liquid or bulk material reaches a specific level within a tank, silo, or bin.

· Generate an electrical signal (on/off or analog) based on the detected level.

· This signal can be used to control pumps, valves, alarms, or other equipment to maintain desired fill levels, prevent overflows, or initiate refilling processes.

Types of Level Switches:

The choice of level switch depends on the type of material being monitored (liquid or solid) and the desired functionality. Here are some common types:

· Float Level Switches:

o A simple and reliable option for liquids.

o A buoyant float rises or falls with the liquid level, triggering a switch mechanism at preset high or low points.

· Displacer Level Switches:

o A displacer element suspended in the liquid moves due to buoyancy changes.

o This movement is detected by a magnetic or mechanical linkage, activating the switch at specific levels.

· Conductivity Level Switches:

o For conductive liquids.

o Electrodes at set points detect conductivity when submerged, indicating the liquid level reaching that point. (Not suitable for non-conductive liquids like oil)

· Ultrasonic Level Switches:

o Emit ultrasonic sound pulses and measure the time it takes for the echo to return.

o This time difference translates to the distance to the material surface, indicating the level. (Suitable for liquids, slurries, and some solids)

· Optical Level Switches:

o Use light beams to detect the presence or absence of material at a specific point.

o Can be suitable for clear liquids or opaque solids depending on the technology (e.g., photoelectric, light reflection).

· Radio Frequency (RF) Admittance Level Switches:

o Emit high-frequency radio waves to sense the presence or absence of material.

o Can be effective for liquids, slurries, and some solids with varying dielectric properties.

· Vibrating Fork Level Switches:

o A tuning fork vibrates at a specific frequency.

o When the material contacts the fork and dampens the vibration, the switch detects the change and indicates a high level. (Suitable for liquids, slurries, and some solids)

· Magnetostrictive Level Switches:

o Utilize a sound wave traveling through a rod to measure the level.

o The presence of material affects the wave propagation, triggering the switch at specific points. (Suitable for liquids and some solids)

Specifications to Consider When Choosing a Level Switch:

· Material Type: Liquid or bulk solid (and its properties like viscosity, abrasiveness)?

· Level Detection Points: High level, low level, or multiple points?

· Operating Temperature and Pressure: Compatible with the tank environment?

· Wetted Materials: Materials the switch will be in contact with (compatibility)?

· Electrical Rating: Output voltage and current requirements for connected equipment.

· Enclosure Rating: NEMA rating for protection against dust, moisture, or hazardous locations.

· Desired Features: Alarm contacts, control relays, data logging capabilities?

Additional Considerations:

· Cost: Level switches range in price depending on complexity and features.

· Ease of Installation and Maintenance: Consider accessibility and cleaning requirements.

· Approvals: Ensure the switch meets any regulatory requirements for your application.