Flow Meter

Leading Manufacturers, Exporters, Wholesaler of Gas Flow Meter, Insertion Flow Meter, Oil Flow Meter, Open Channel Flow Meter, Sa Vortx and Steam Flow Meter, Ultrasonic Flow Meter, Water Flow Meters, Digital Flow Meter, Electromagnetic Flow Meter, Rota Meter, Flow Control Valves, Flow Meters and Flow Switches from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Driven Type | Electric |

| Shape | Rectangular |

| Color | Grey Blue |

| Pressure | Low Pressure |

| Operating Type | Automatic |

| Voltage | 220V |

| Packaging Type | Carton Box |

| Country of Origin | India |

Gas flow meters measure the volumetric or mass flow rate of various gases. They come in different configurations to handle the specific properties of gases, such as low density, potential corrosiveness, and wide viscosity ranges. Here's a breakdown of typical specifications to consider when selecting a gas flow meter:

General Specifications:

· Flow Meter Type: Gas flow meters utilize various technologies, each with its advantages and limitations. Common types include:

o Positive Displacement (PD) Meters: These trap a fixed volume of gas and count the number of times the volume is filled and emptied, providing accurate measurement for various gas types. Examples include oval gear, rotary vane, and nutating disc meters.

o Thermal Mass Flow Meters: These meters directly measure the mass flow rate of gas by sensing the heat transfer between the gas flow and heated sensor elements. They offer excellent accuracy but can be more expensive.

o Coriolis Flow Meters: These advanced meters measure mass flow rate by utilizing the Coriolis effect (vibration of a flowing mass). They provide high accuracy for various gases but are complex and costly.

o Turbine Flow Meters: These meters use a rotor with blades that spins based on the flow rate of the gas. They are generally good for cleaner, less dense gases and offer good repeatability.

o Ultrasonic Flow Meters: These meters use ultrasonic waves to measure gas velocity within a pipe. They can handle various gases, including those with entrained particles, but require careful consideration of pipe size and gas composition for accurate measurement.

· Pipe Size: The diameter of the pipe the meter is designed for (e.g., 1/2 inch, 2 inch, etc.). Ensure it matches your pipeline diameter.

Performance Specifications:

· Flow Rate Range: The range of flow rates the meter can accurately measure. Select a meter with a range that covers your expected gas flow rates.

· Accuracy: Expressed as a percentage of reading (% of reading) or reading plus/minus a fixed value. Typical accuracy for good quality meters is ±0.5% to ±2% of reading, with thermal mass flow meters offering higher accuracy.

· Repeatability: The ability of the meter to produce consistent readings for the same flow rate. High repeatability is desirable for reliable measurements.

· Pressure Rating: The maximum pressure the meter can withstand without failure. Ensure it meets the operating pressure in your system.

· Temperature Rating: The range of temperatures the meter can function within without compromising performance. Consider both ambient and gas temperatures, as they can affect gas density and flow characteristics.

Material Specifications:

· Body Material: The material of the meter body, chosen for compatibility with the gas type, pressure rating, and potential corrosion resistance. Common materials include stainless steel, aluminum, and various alloys.

· Wetted Materials: The materials of parts coming into contact with the gas, critical for compatibility to avoid contamination or degradation.

Output Specifications:

· Output Signal: The electrical signal the meter generates to represent the flow rate. Common options include:

o Pulse output: Generates a pulse for each unit of volume or rotor revolution. The pulse frequency is proportional to the flow rate.

o Frequency output: Outputs a continuous electrical signal with a frequency proportional to the flow rate.

o Analog output: Provides a 4-20mA current loop or 0-10V voltage signal representing the flow rate.

Additional Features:

· Totalizer: A built-in function that accumulates the total volume of gas that has flowed through the meter over time.

· Temperature Sensor (Optional): Some models include a temperature sensor to allow for temperature compensation and improve accuracy, especially for variable temperature applications.

· Flow Conditioning (Optional): Certain applications may require flow conditioners upstream of the meter to ensure a smooth and consistent gas flow for accurate measurement.

· Communication Protocols (Optional): Some advanced models offer communication protocols (e.g., Modbus) for remote monitoring and configuration.

Factors to Consider When Selecting a Gas Flow Meter:

· Gas Type: Identify the specific gas you'll be measuring (e.g., natural gas, compressed air, nitrogen) as this can influence flow meter selection and material compatibility.

· Flow Rate Range: Select a meter with a range that comfortably covers your anticipated gas flow rates.

· Accuracy Requirements: Consider the required accuracy level for your application. Thermal mass flow meters generally offer the highest accuracy.

· Pressure and Temperature Rating: Choose a meter with pressure and temperature ratings exceeding your operating conditions.

· Material Compatibility: Ensure the meter's body and wetted materials are compatible with your gas type to avoid issues.

· Output Signal: Select an output signal compatible with your data acquisition system.

· Additional Features: Consider optional features like a totalizer, temperature

Additional Considerations for Gas Flow Meters (Continued)

· Pipe Size: Ensure the chosen meter's pipe size rating matches your pipeline diameter.

· Installation: Consider the ease of installation for the selected meter type. Some meters, like positive displacement meters, may require interrupting the flow for installation, while others like ultrasonic meters can be clamp-on for non-invasive installation.

· Cost: Gas flow meters vary in price depending on technology, accuracy, and features. Consider your budget and prioritize features essential for your application.

· Regulatory Requirements: In some industries, specific regulatory requirements might dictate the type of gas flow meter you can use.

Here's a table summarizing the common gas flow meter types to aid selection:

|

Flow Meter Type |

Advantages |

Disadvantages |

Typical Applications |

|

Positive Displacement (PD) Meters |

Accurate for various gases, good repeatability |

Can be bulky, pressure drop across meter, moving parts require maintenance |

Natural gas flow measurement, compressed air monitoring, industrial process control |

|

Thermal Mass Flow Meters |

Excellent accuracy, direct mass flow measurement |

Higher cost, sensitive to temperature variations |

Commercial and industrial gas flow measurement, emissions monitoring |

|

Coriolis Flow Meters |

High accuracy for various gases, mass flow measurement |

Most expensive option, complex technology |

High-value gas measurement, custody transfer applications |

|

Turbine Flow Meters |

Good for clean, less dense gases, simple design |

Lower accuracy for dusty or dirty gases |

Natural gas flow measurement, air flow monitoring in pneumatic systems |

|

Ultrasonic Flow Meters |

Non-invasive installation, handles gases with entrained particles |

Requires careful consideration of pipe size and gas composition, accuracy can be affected by gas properties |

Utility gas metering, biogas flow measurement |

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | SA |

| Accuracy | Any |

| Country of Origin | India |

| Payment Terms | T/T |

| Packaging Details | Wooden Box |

Electromagnetic flow meter overview line size : 150 nb to 2000 nb type of output : 1) 4 to 20 ma dc accuracy : +- 2% f. S. (for 20 to 100% flow) material of construction : electrode - ss 316l power supply : 90 - 250 v ac, 50 hz power consumption : < 10 va salient features suitable for conductive liquid. Absolutely maintenance free. Insertion type. Local indication through lcd. Simple & cost effective construction. Outstanding accuracy. Flow measurement in forward & reverse direction on demand. Empty pipe indication on demand. Material options depending upon process data. Universal power supply. Communication port on demand. Communication port on demand. Hart compatible (optional) software for multiple flow meter integration & data logging (optional)

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Polished |

| Driven Type | Battery |

| Color | Grey Blue |

| Pressure | Medium Pressure |

| Operating Type | Automatic |

| Voltage | 220V |

| Packaging Type | Carton Box |

| Country of Origin | India |

| Payment Terms | T/T |

| Packaging Details | Box |

Oil flow meter we are involved in the manufacturing and exporting of flow meters that are integrated with advance technology for better performance. These flow meters are widely acclaimed by the clients for their distinctive features. We offer flow meters in diverse specifications to cater the needs of the domestic as well as international market. Salient features • high durability • reliability • precision engineering • accurate measurements range of flow meters includes • pd meters • turbine meters • orifice meters • carioles meters • ultrasonic meters • paddle wheel flow meter • electromagnetic flow meter • mass flow meter • thermal mass flow meter • insertion flow meter

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Soham |

| Material | Mild Steel |

| Finishing | Polished |

| Driven Type | Electric |

| Shape | Rectangular |

| Color | Grey Blue |

| Power | 24VDC Or 220VAC |

| Pressure | Low Pressure |

| Operating Type | Automatic |

| Usage | Industrial, Laboratory, Chemical Flow Measurement, Water And Chemicals, ETP/STP/WSTP/CTP |

| Voltage | 110V |

| Packaging Type | Carton Box |

| Type | Turbine Flow Meter |

| Phase | Single Phase |

| Country of Origin | India |

| Display | Local |

| Corrosion Resistance | Yes |

Open Channel Ultrasonic Flow Meter

Exclusive sensor for Open Channel flow

High accuracy, high stability

Downloading logging data by USB

Data logging for long period

simple structure

Open channel ultrasonic is a flow measurement device best suited for storage tanks and open channels flow. It has a local display with buttons for quick and easy commissioning

Temperature compensation is integrated and can be equipped with an external sensor for dynamic temperatrue compensation.

The automatic false eacho detection toghther with easy set up makes it reliable and trustworthy.

The measured level value is converted into the rate of flow in

specific weirs therefore the accurate level value is very important.

The measured flow information saves in memoery which can be downloaded by USB or transmitted by the digital communication such RS 485 or Modbus, the built EEPORM digital memory makes sure that the data will not lost in case of power failure

Main Specification :

Measurement method Ultrasonic Non-Contacting

Measurement Range 0.1l/s〜9999m3/s

Cumulative Flow 99999999m3

Display LCD displays the instantaneous flow and cumulative Flow

Ambient temp. : -30°C ~ +70°C

Power Supply : 100-230VAC

Blind area : 0.25m〜0.5m

Distance precision : 0.3%( standard condi

Distance resolution 1 MM

Flow precision : 1%〜5%( subject to the type of weir plate)

Pressure : Less than 4 atmosphere pressure

Analog output : 4〜20mA

Digital output : RS485、Modbus agreement or customized agreement

Power voltage : DC24V/AC220V,built-in lightning proof device Ambient

IP Protection IP 65

Salient Features:

With the die casting aluminum alloy waterproof and explosion-proof shell, be explosion-proof and safe.

For the circuit design, high-quality power modules are selected from the power supply and highly stable

and reliably imported devices are used as its components. It can fully replace imported foreign meters of

the same type.

Patent sonic-wave intelligent technology software can make intelligent zed echo analysis. It needs neither debugging nor other special steps. This technology has functions of dynamic thinking and dynamican alysis.Our sonic-wave intelligent patent technology improves the precision (up to 0.3%) greatly. It can resist various interference waves.

This product is a kind of non-contact instrument. As it doesn’t contact the liquid directly, the failure rate is low. This product is designed with different installation methods. The user can make calibration independently as described in the manual

All incoming and outgoing lines have lightning proof and short-circuit proof functions.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Color | Grey Blue |

| Pressure | Low Pressure, Medium Pressure, High Pressure |

| Operating Type | Automatic |

| Usage | Industrial |

| Voltage | 220V |

| Packaging Type | Carton Box |

| Certificate | CE Certified, ISO 9001:2008 |

| Specialities | Accuracy |

| Type | Steam Flow Meter |

| Country of Origin | India |

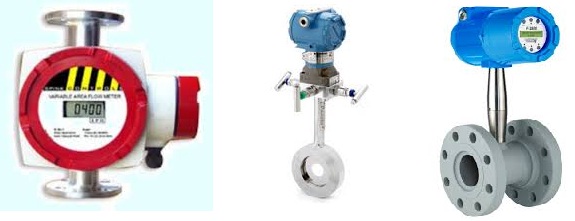

Vortex Flow Meter: Reliable Measurement for Various Fluids

The vortex flow meter is a versatile instrument used to measure the volumetric flow rate of fluids within a pipeline. It operates based on the principle of vortex shedding, making it suitable for a wide range of liquids, gases, and even steam. Here's a breakdown of the product description and key specifications to consider when selecting a vortex flow meter:

Product Description:

Vortex flow meters utilize a bluff body (a shedder) strategically placed within the flow stream. As the fluid flows past the bluff body, vortices ( swirling patterns) are shed alternately from either side. The frequency of vortex shedding is directly proportional to the flow velocity. The meter's sensor, typically piezoelectric or ultrasonic, detects these pressure fluctuations caused by the vortices. The meter's electronics then convert the vortex shedding frequency into a flow rate measurement.

Benefits of Vortex Flow Meters:

· Wide range of applications: Capable of measuring flow rates for various fluids, including liquids, gases, and steam (with proper conditioning).

· No moving parts: Offers reliable operation with minimal maintenance requirements due to the absence of moving parts.

· Good accuracy: Can achieve accuracy of ±0.5% to ±2% of reading under ideal conditions.

· Low pressure drop: The shedder creates minimal obstruction within the pipe, resulting in low pressure drop across the meter.

· Wide flow rate range: Can handle a broad spectrum of flow rates, making them adaptable to diverse applications.

Specifications to Consider When Selecting a Vortex Flow Meter:

· Flow Meter Type: Vortex flow meters come in various configurations, each with slight performance variations. Common types include:

o Standard Vortex Flow Meter: The most common type, suitable for clean liquids and gases.

o Split Body Vortex Flow Meter: Easier to install/remove from existing pipelines without interrupting flow.

o Low Flow Vortex Flow Meter: Designed for measuring lower flow rates with good accuracy.

· Pipe Size: The diameter of the pipe the meter is designed for (e.g., 1 inch, 4 inch, etc.). Ensure it matches your pipeline diameter.

· Flow Rate Range: Select a meter with a range that comfortably covers your anticipated flow rates for the chosen fluid type.

· Accuracy: Consider the required accuracy level for your application.

· Pressure Rating: The maximum pressure the meter can withstand without failure. Ensure it meets the operating pressure in your system.

· Temperature Rating: The range of temperatures the meter can function within without compromising performance. Consider both ambient and fluid temperatures.

· Material Compatibility: The meter's body and wetted materials should be compatible with the fluid type to avoid corrosion or measurement issues. Common materials include stainless steel, exotic alloys, and various plastics depending on the application.

· Output Signal: The electrical signal the meter generates to represent the flow rate. Common options include:

o Pulse output: Generates a pulse for each unit of volume or vortex shedding event. The pulse frequency is proportional to the flow rate.

o Analog output: Provides a 4-20mA current loop or 0-10V voltage signal representing the flow rate.

Additional Features (Optional):

· Temperature Sensor: Improves accuracy by compensating for the effect of temperature on fluid viscosity, which can influence vortex shedding.

· Remote Electronics: Enables mounting the meter's electronics away from the pipeline in harsh environments or for easier access.

· Communication Protocols (Optional): Some advanced models offer communication protocols (e.g., Modbus) for remote monitoring and configuration.

Applications of Vortex Flow Meters:

· Water and Wastewater Treatment: Monitoring flow rates of water, effluent, and chemical solutions.

· Chemical and Process Industries: Measuring flow rates of various chemicals, gases, and light hydrocarbons.

· Oil and Gas Production: Monitoring flow rates of crude oil, refined products, and natural gas (with proper conditioning).

· Power Generation: Measuring steam flow rates, compressed air, and other critical fluids.

· HVAC Systems: Monitoring chilled water flow rates and air flow for building temperature control

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Polished |

| Driven Type | Battery |

| Color | Grey Blue |

| Pressure | Low Pressure, Medium Pressure, High Pressure |

| Operating Type | Automatic |

| Usage | Industrial |

| Packaging Type | Carton Box |

| Country of Origin | India |

Ultrasonic flow meter we are involved in the manufacturing and exporting of flow meters that are integrated with advance technology for better performance. These flow meters are widely acclaimed by the clients for their distinctive features. We offer flow meters in diverse specifications to cater the needs of the domestic as well as international market. Salient features • high durability • reliability • precision engineering • accurate measurements range of flow meters includes • pd meters • turbine meters • orifice meters • carioles meters • ultrasonic meters • paddle wheel flow meter • electromagnetic flow meter • mass flow meter • thermal mass flow meter • insertion flow meter

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Water Flow Meters |

| Finish | Finie Finish |

| Usage/Application | industrial |

| Material | Metal |

| Country of Origin | India |

| Packaging Type | Box Packaging |

WATER FLOW METER We are involved in the Manufacturing and Exporting of Flow Meters that are integrated with advance technology for better performance. These Flow Meters are widely acclaimed by the clients for their distinctive features. We offer Flow Meters in diverse specifications to cater the needs of the domestic as well as international market. Salient Features High durability Reliability Precision engineering Accurate measurements Range of Flow Meters Includes PD meters Turbine meters Orifice meters Carioles meters Ultrasonic meters Paddle wheel flow meter Electromagnetic flow meter Mass flow meter Thermal mass flow meter Insertion flow meter Line Size 14" - 300 MM Media Any Pressure Any Temperature Any Connection Thread EndFlange EndTriclover End

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Color | Silver |

| Pressure | Low Pressure, Medium Pressure, High Pressure |

| Operating Type | Automatic |

| Usage | Industrial |

| Packaging Type | Carton Box |

| Certificate | CE Certified |

| Country of Origin | India |

for any more details about this product kindly contact us.

soham automation

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Polished |

| Driven Type | Electric |

| Shape | Rectangular |

| Pressure | Low Pressure, Medium Pressure, High Pressure |

| Operating Type | Automatic |

| Usage | Industrial, Laboratory |

| Country of Origin | India |

Electromagnetic Flow Meter: A Non-invasive Solution for Conductive Liquids

The electromagnetic flow meter (also known as a mag meter) is a versatile instrument used to measure the volumetric flow rate of conductive liquids within a pipe. Unlike other flow meters that utilize moving parts or require installation disruptions, mag meters offer a non-invasive and obstruction-free measurement approach. This makes them ideal for various industrial applications involving liquids with:

· Conductivity: The key element for electromagnetic flow measurement. The liquid must be conductive enough to enable the meter to function. Examples include:

o Water-based solutions (e.g., saltwater, acids, alkalis, slurries)

o Chemicals and solvents

o Food and beverage products

Operating Principle:

Electromagnetic flow meters utilize Faraday's Law of electromagnetic induction. The meter generates a magnetic field across the diameter of the pipe through a pair of coils. When conductive liquid flows through this magnetic field, a voltage (electromotive force) is induced in the liquid perpendicular to both the flow and the magnetic field. This voltage is directly proportional to the average velocity of the flowing liquid. Electrodes positioned on the pipe wall capture this voltage, and the meter's electronics convert it into a flow rate measurement.

Benefits of Electromagnetic Flow Meters:

· Non-invasive measurement: No moving parts or obstructions within the pipe, minimizing pressure drop and potential contamination issues.

· Wide range of applications: Suitable for various conductive liquids, including slurries and those with entrained solids or gas bubbles.

· Accurate measurement: Capable of achieving high accuracy (typically ±0.5% to ±1% of reading) under ideal conditions.

· Wide flow rate range: Can handle a broad spectrum of flow rates, making them adaptable to diverse applications.

· Low maintenance: No moving parts generally require less maintenance compared to mechanical meters.

Considerations for Using Electromagnetic Flow Meters:

· Liquid Conductivity: The meter requires a minimum level of conductivity in the liquid for accurate measurement. Non-conductive liquids (e.g., oil, pure hydrocarbons) are not suitable.

· Pipe Material: Non-metallic pipes (e.g., plastic) can weaken the magnetic field, affecting measurement accuracy. For these cases, grounding rings or liners might be needed.

· Minimum Flow Rate: There's a minimum flow rate below which the meter's accuracy can be compromised.

· Installation Requirements: Straight pipe sections are typically required upstream and downstream of the meter for optimal performance.

Applications of Electromagnetic Flow Meters:

· Water and Wastewater Treatment: Monitoring water flow rates, controlling chemical dosing, and effluent measurement.

· Chemical and Process Industries: Measuring flow rates of various chemicals, slurries, and process liquids.

· Food and Beverage Production: Monitoring flow rates of syrups, juices, and other conductive food products.

· Pulp and Paper Industry: Measuring flow rates of pulp slurries and other process liquids.

· Pharmaceutical Manufacturing: Monitoring flow rates of sterile liquids and solutions.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel |

| Color | Black |

| Feature | Easy To Maintain |

| Type | Rotameters |

| Country of Origin | India |

| Payment Terms | T/T |

A rotameter, also known as a variable area flow meter, is a simple and cost-effective device used to measure the volumetric flow rate of liquids or gases in a closed tube. Here's a quick breakdown:

· Function: Measures the flow rate by observing the position of a float suspended within a tapered tube.

· Design:

o Consists of a transparent, vertical tube with a wider diameter at the bottom and a narrower diameter at the top.

o A freely moving float is positioned inside the tube.

· Operation:

o As the flow rate increases, the drag force on the float pushes it higher in the tapered tube.

o The higher the float position, the greater the flow rate.

o A scale marked on the outside of the tube allows you to directly read the flow rate based on the float's position.

· Advantages:

o Simple and easy to understand operation.

o Relatively inexpensive compared to other flow meters.

o Works for both liquids and gases (depending on the model).

o No external power required for operation (in some models).

· Disadvantages:

o Not very accurate for precise flow measurement.

o Accuracy can be affected by changes in fluid viscosity or temperature (for liquids).

o Limited data output (typically just flow rate).

Applications:

· Rotameters are commonly used in various industries for:

o Monitoring flow rates in pipelines for chemical processing, water treatment, and food and beverage production.

o Balancing flow rates in irrigation systems.

o Measuring gas flow in laboratories or for medical applications (e.g., oxygen flow rate).

| Business Type | Manufacturer, Exporter, Supplier |

| Valve Type | Gate |

| Material | Metal |

| Media | Water |

| Connection Type | Flanged |

| Temperature Pressure | Medium Temperature Pressure |

| Automatic Grade | Automatic |

| Brand Name | SA |

| Color | Sky Blue |

| Mounting Type | Vertical |

| Packaging Type | Wooden Box |

| Country of Origin | India |

| Payment Terms | T/T |

| Packaging Details | Box |

Flow Control Valve

Flow control valves are essential components in various industrial process control systems and fluid handling applications. They regulate the flow rate of liquids, gases, or slurries by adjusting the flow path within the valve. Here's a breakdown of their typical specifications to consider when selecting a flow control valve:

General Specifications:

· Valve Type: This refers to the specific design and mechanism used for flow control. Common types include:

o Globe valves: Offer good throttling (gradual flow adjustment) capabilities.

o Needle valves: Provide precise flow control for smaller lines.

o Butterfly valves: Known for their simple design and good on/off flow control.

o Diaphragm valves: Well-suited for viscous fluids and offer good shutoff capabilities.

o Ball valves: Offer excellent shutoff and are easy to maintain.

· Valve Size: This specifies the pipe diameter that the valve is designed for (e.g., 1/2 inch, 2 inch, etc.).

· Flow Rate Range: The range of flow rates the valve can effectively control.

· Body Material: The material of the valve body chosen based on factors like pressure rating, compatibility with the fluid, and corrosion resistance. Common materials include stainless steel, brass, cast iron, PVC, etc.

Performance Specifications:

· Pressure Rating: The maximum pressure the valve can withstand without failure. This should be compatible with the operating pressure in your system.

· Temperature Rating: The range of temperatures the valve can function within without compromising performance. The material selection and packing materials also influence this.

· Cv Rating (Flow Coefficient): An indicator of the valve's flow capacity. Higher Cv allows for higher flow rates.

· Leakage Rate: The amount of fluid that bypasses the closed valve seat, typically classified into classes like bubble-tight or low-leakage.

Control Mechanism Specifications:

· Actuation Type: This refers to the method used to open or close the valve:

o Manual: Operated by a handwheel or lever.

o Pneumatic: Uses compressed air for actuation.

o Electric: Uses an electric motor for actuation.

o Solenoid: Employs a solenoid coil for quick on/off actuation.

· Control Signal (Applicable for Pneumatic/Electric Actuation): The type of signal used to control the actuator (e.g., 4-20mA current loop for proportional control).

Additional Features:

· Cracking Pressure (Relief Valves): The pressure at which a relief valve opens to prevent overpressure situations.

· Flow Direction (Check Valves): Designed to allow flow in one direction and prevent flow reversal.

· Material of Construction (Seals and Packing): The materials used for seals and packing should be compatible with the fluid and temperature to prevent leaks.

· Bonnet Design (Globe Valves): Refers to the design of the valve bonnet which holds the internal components. Bolted bonnets offer easy maintenance access.

Factors to Consider When Selecting a Flow Control Valve:

· Application Requirements: Consider the type of fluid, desired flow control characteristics (on/off or throttling), and pressure/temperature conditions in your system.

· Valve Type: Choose a valve type that best suits your flow control needs (e.g., globe valve for throttling, butterfly valve for on/off).

· Valve Size: Select a valve size that matches your pipe diameter and desired flow rate capacity.

· Material Selection: Choose body, seal, and packing materials compatible with your fluid, pressure, temperature, and potential corrosion concerns.

· Actuation Type: Pick an actuation method (manual, pneumatic, electric) that aligns with your control system requirements.

· Additional Features: Consider features like cracking pressure (relief valves), flow direction (check valves), or bonnet design based on your specific application needs.

By understanding these specifications and factors, you can select a flow control valve that effectively regulates fluid flow and aligns with the specific requirements of your industrial process control system or fluid handling application.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Finishing | Polished |

| Driven Type | Battery |

| Color | Grey Blue |

| Pressure | Low Pressure, Medium Pressure, High Pressure |

| Operating Type | Automatic |

| Application | Laboratory |

| Voltage | 220V |

| Packaging Type | Carton Box |

| Certificate | CE Certified |

| Country of Origin | India |

We are involved in the Manufacturing and Exporting of Flow Meters that are integrated with advance technology for better performance. These Flow Meters are widely acclaimed by the clients for their distinctive features. We offer Flow Meters in diverse specifications to cater the needs of the domestic as well as international market.

Salient Features

- High durability

- Reliability

- Precision engineering

- Accurate measurements

Range of Flow Meters Includes

- PD meters

- Turbine meters

- Orifice meters

- Carioles meters

- Ultrasonic meters

- Paddle wheel flow meter

- Electromagnetic flow meter

- Mass flow meter

- Thermal mass flow meter

- Insertion flow meter

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Surface Finishing | Polished |

| Shape | Rectengular |

| Color | Grey |

| Design | Standard |

| Condition | New |

| Type | Flow Switches |

| Country of Origin | India |

| Max. Voltage | 240 V DC |

Flow switches, also known as flow sensors or flow indicators, are devices used to monitor and signal the presence, absence, or rate of fluid flow within a pipe or duct. They play a crucial role in various industrial process control and fluid handling applications. Here's a breakdown of typical specifications to consider when selecting a flow switch:

General Specifications:

· Switch Type: Flow switches come in various designs, each with its own operating principle:

o Paddle Flow Switches: These utilize a hinged paddle or flapper within the flow stream. When flow reaches a certain velocity, the paddle deflects, triggering a micro switch. They are suitable for basic on/off flow indication.

o Positive Displacement Flow Switches: These have a rotor or disc that rotates due to flow. As the rotor/disc completes a specific number of rotations, a switch is activated. They offer good repeatability for flow rate monitoring.

o Thermal Flow Switches: These measure the temperature difference between a heated element and the flowing fluid. A change in flow rate affects the temperature difference, triggering the switch. They are well-suited for low flow applications.

o Vortex Flow Switches: These create vortices (swirling patterns) in the flow stream. The frequency of vortex shedding is proportional to the flow rate, allowing for flow rate monitoring and switching.

· Pipe Size: The diameter of the pipe the flow switch is designed for (e.g., 1/2 inch, 2 inch, etc.). Ensure it matches your pipeline diameter.

Performance Specifications:

· Set Point (Adjustable or Fixed): This defines the flow rate at which the switch activates (on point) or deactivates (off point). Some models allow for set point adjustment, while others have fixed settings.

· Flow Rate Range: The range of flow rates the switch can operate within. Choose a switch with a range that covers your desired flow activation/deactivation points.

· Deadband (Optional): The difference between the flow rate at which the switch activates (on point) and the flow rate at which it deactivates (off point). A higher deadband helps prevent rapid switching due to minor flow fluctuations.

· Repeatability: The ability of the switch to consistently activate/deactivate at the set point for the same flow rate. High repeatability is desirable for reliable operation.

· Pressure Rating: The maximum pressure the switch can withstand without failure. Ensure it meets the operating pressure in your system.

· Temperature Rating: The range of temperatures the switch can function within without compromising performance. Consider both ambient and fluid temperatures.

Material Specifications:

· Body Material: The material of the flow switch body, chosen for compatibility with the fluid type, pressure rating, and potential corrosion resistance. Common materials include stainless steel, brass, PVC, etc.

· Wetted Materials: The materials of parts coming into contact with the fluid, critical for compatibility to avoid wear, degradation, or contamination.

Electrical Specifications:

· Switching Mechanism: Specify the type of switching mechanism employed (e.g., micro switch, reed switch).

· Output Signal: The electrical signal generated by the switch upon activation/deactivation. Common options include:

o SPST (Single Pole Single Throw): Opens or closes a single circuit path.

o SPDT (Single Pole Double Throw): Switches the connection between two different circuits.

Additional Features:

· Time Delay (Optional): A user-adjustable delay in switch activation/deactivation to prevent false triggering due to momentary flow fluctuations.

· Low Flow Cut-off (Optional): A feature that ignores very low flow rates that might be caused by noise or measurement errors.

· Alarm Output (Optional): Some models provide an additional output for connecting alarms or indicating switch status.

Factors to Consider When Selecting a Flow Switch:

· Application Requirements: Identify whether you need a simple on/off flow indication or flow rate monitoring.

· Pipe Size: Choose a switch designed for the diameter of your pipeline.

· Fluid Type: Consider the fluid's compatibility with the switch's materials to avoid corrosion or functionality issues.

· Flow Rate Set Point: Select a switch with a set point (adjustable or fixed) that aligns with your desired flow activation/deactivation point.

· Pressure and Temperature Rating: Choose a switch with pressure and temperature ratings exceeding your operating conditions.

· Electrical Specifications: Ensure the switch's output signal is compatible with your control system.

· Additional Features: Consider optional features like time delay, low flow cut-off, or alarm output based on your specific needs.