| Business Type | Manufacturer, Exporter, Supplier |

| Application | Multiwork |

| Voltage | 440V |

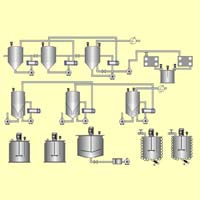

An automation system integrator, often abbreviated as ASI, acts as a bridge between the world of automation technology and the specific needs of a manufacturing or industrial facility. They are the orchestra conductors of the automation world, bringing together various components and expertise to create a smooth-running symphony of efficient production.

Function:

- Unlike manufacturers who focus on specific automation components (e.g., robots, sensors), ASIs specialize in designing, implementing, and maintaining entire automation systems.

- They take a holistic view of a client's needs, analyzing their processes and identifying areas for improvement through automation.

- ASIs then design a customized solution that integrates various components – hardware (robots, controllers, sensors), software (control programs), and communication networks – to create a seamless and efficient automated system.

Services Provided by ASIs:

- Feasibility Studies and Process Analysis: Evaluate a client's current processes to determine the viability of automation and identify the most suitable areas for improvement.

- System Design and Engineering: Develop a customized automation solution tailored to the specific needs of the client's facility. This includes selecting the appropriate equipment, designing the control logic, and ensuring compatibility with existing systems.

- Project Management and Procurement: Oversee all aspects of the automation project, from equipment procurement and scheduling to budget management.

- System Integration and Installation: Physically install the automation equipment, integrate it with existing systems, and ensure proper communication between all components.

- Commissioning and Testing: Conduct rigorous testing and validation of the entire system to ensure it functions as designed, meets safety standards, and achieves the desired performance metrics.

- Training and After-Sales Support: Provide training for personnel on operating and maintaining the new automated system, along with ongoing support to address any issues and optimize performance.

Benefits of Working with an ASI: - Expertise and Experience: ASIs possess a deep understanding of automation technologies and can leverage their experience to design and implement optimal solutions.

- Holistic Approach: They take a comprehensive view of your needs, considering not just the automation equipment but also integration with existing systems and processes.

- Reduced Risk: By managing the entire project, ASIs minimize risks associated with automation implementation.

- Faster Time to Completion: Their experience and established relationships with vendors can expedite the project timeline.

- Ongoing Support: ASIs provide valuable after-sales support to ensure your automated system continues to operate efficiently.

Choosing the Right Automation System Integrator:

Selecting the right ASI is crucial for the success of your automation project. Here are some key factors to consider: - Industry Experience: Choose an ASI with a proven track record in your specific industry and an understanding of the unique challenges you face.

- Expertise and Capabilities: Ensure they have the necessary expertise in the specific automation technologies you require (e.g., robotics, motion control, SCADA systems).

- Project Management Skills: Evaluate their project management approach and their ability to communicate effectively throughout the project.

- After-Sales Support: Prioritize ASIs offering comprehensive after-sales support programs to ensure long-term system performance.

- References and Case Studies: Review their past projects and client testimonials to understand their capabilities and approach.

In Conclusion:

Automation system integrators play a vital role in helping businesses leverage the power of automation to achieve their production and efficiency goals. By partnering with the right ASI, you can ensure a smooth transition to automation, maximize the benefits of your investment, and gain a competitive edge in your industry.

Looking for "Automation System Integrators" ?

piece

Explore More Products