| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Color | Black |

| Condition | New |

| Click to view more | |

Product Details

Level indicators, unlike level switches, provide a continuous visual representation of the level of liquid or bulk solids within a container. They offer a more informative way to monitor fill levels compared to level switches that simply trigger an on/off signal at preset points. Here's a breakdown of level indicators and their various types:

Function:

· Provide a direct visual indication of the level of liquid or bulk material in a tank, bin, or silo.

· Allow for continuous monitoring of fill levels without relying solely on electrical signals.

· Can be used for various applications, including process monitoring, inventory control, and ensuring safety by preventing overfills.

Types of Level Indicators:

The choice of level indicator depends on the type of material being monitored (liquid or solid) and the desired level of detail:

· Sight Glasses (Tubular Level Gauges):

o Simple and cost-effective option for liquids.

o Consists of a transparent tube or window mounted on the side of a tank, allowing you to see the liquid level directly.

o Suitable for various tank sizes and pressures depending on the material.

· Reflex Level Gauges:

o For liquids with different refractive indexes (light bending properties) than the gauge material.

o The interface between the liquid and empty space appears as a distinct line due to refraction, indicating the level.

· Magnetic Level Indicators:

o Utilize a magnetic float inside the tank connected to an external indicator with red and white sections.

o The red section rises with the float as the liquid level increases, providing a visual indication. (May not be suitable for all liquids or environments with strong magnetic fields)

· Electronic Level Indicators:

o Employ electronic sensors and a digital display to show the liquid level.

o May use various sensing technologies like ultrasonic or radar and offer features like level scaling and data logging.

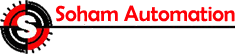

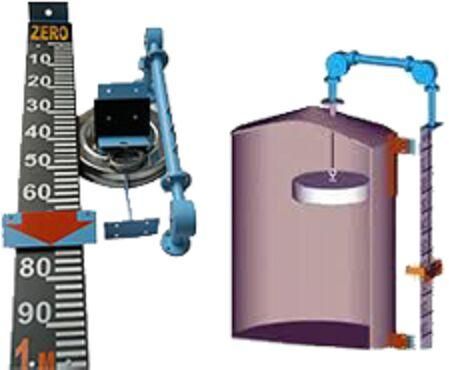

· Float and Board Level Indicators:

o Primarily for large tanks with bulk solids.

o A float rides on the surface of the material, connected by a cable and pulley system to an indicator board outside the tank.

o The board moves up or down to visually represent the fill level.

Additional Considerations When Choosing a Level Indicator:

· Material Type: Liquid or bulk solid (and its properties like transparency, viscosity)?

· Tank Material and Pressure: Compatible with the sight glass or enclosure material?

· Temperature Range: Suitable for the operating environment?

· Desired Level Detail: Basic level indication or need for precise measurements?

· Visibility Requirements: Viewing distance and ambient light conditions?

· Cost and Maintenance: Evaluate initial cost and ease of cleaning or maintenance.

Advantages of Level Indicators:

· Simple and Easy to Use: Provide a clear visual representation of fill levels.

· Reliable Operation: Generally less complex than level switches, offering reliable monitoring.

· Cost-Effective: Many options are affordable, especially for basic level indication.

Disadvantages of Level Indicators:

· Limited Data Output: Do not typically offer data logging or remote monitoring capabilities.

· Accuracy: May not be as precise as some electronic level switches for specific applications.

· Visibility Concerns: Viewing angles or ambient light can affect readability in some cases.

Overall, level indicators provide a valuable tool for visual monitoring of liquid or bulk solid levels in various applications. By considering the type of material, tank conditions, and desired level detail, you can choose the most appropriate level indicator for your needs. They offer a simple, reliable, and cost-effective way to keep an eye on your inventory and ensure safe operation.

Looking for "Float and Board Type Level Indicator" ?

Explore More Products