| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Polished |

| Driven Type | Electric |

| Click to view more | |

Product Details

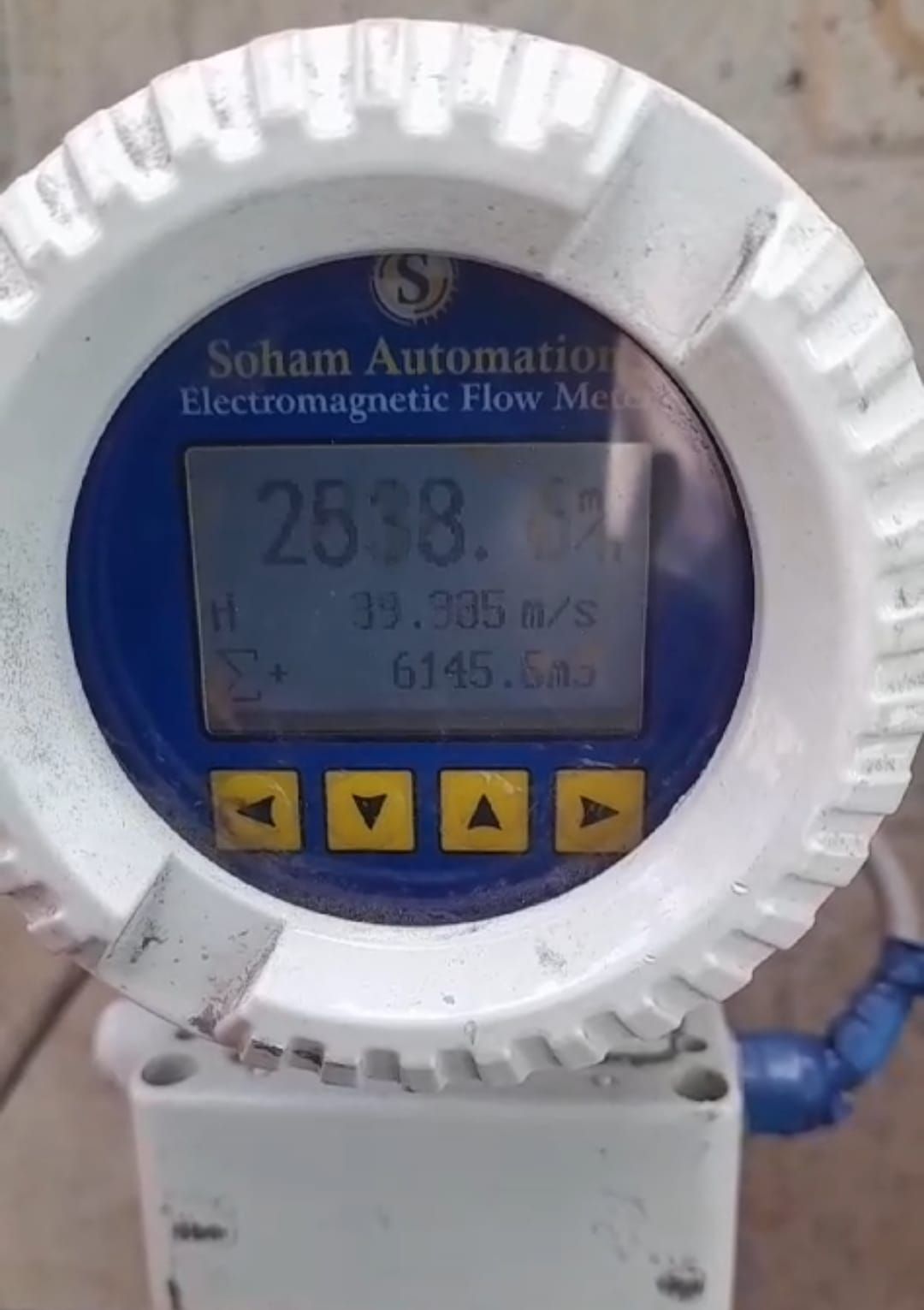

Electromagnetic Flow Meter: A Non-invasive Solution for Conductive Liquids

The electromagnetic flow meter (also known as a mag meter) is a versatile instrument used to measure the volumetric flow rate of conductive liquids within a pipe. Unlike other flow meters that utilize moving parts or require installation disruptions, mag meters offer a non-invasive and obstruction-free measurement approach. This makes them ideal for various industrial applications involving liquids with:

· Conductivity: The key element for electromagnetic flow measurement. The liquid must be conductive enough to enable the meter to function. Examples include:

o Water-based solutions (e.g., saltwater, acids, alkalis, slurries)

o Chemicals and solvents

o Food and beverage products

Operating Principle:

Electromagnetic flow meters utilize Faraday's Law of electromagnetic induction. The meter generates a magnetic field across the diameter of the pipe through a pair of coils. When conductive liquid flows through this magnetic field, a voltage (electromotive force) is induced in the liquid perpendicular to both the flow and the magnetic field. This voltage is directly proportional to the average velocity of the flowing liquid. Electrodes positioned on the pipe wall capture this voltage, and the meter's electronics convert it into a flow rate measurement.

Benefits of Electromagnetic Flow Meters:

· Non-invasive measurement: No moving parts or obstructions within the pipe, minimizing pressure drop and potential contamination issues.

· Wide range of applications: Suitable for various conductive liquids, including slurries and those with entrained solids or gas bubbles.

· Accurate measurement: Capable of achieving high accuracy (typically ±0.5% to ±1% of reading) under ideal conditions.

· Wide flow rate range: Can handle a broad spectrum of flow rates, making them adaptable to diverse applications.

· Low maintenance: No moving parts generally require less maintenance compared to mechanical meters.

Considerations for Using Electromagnetic Flow Meters:

· Liquid Conductivity: The meter requires a minimum level of conductivity in the liquid for accurate measurement. Non-conductive liquids (e.g., oil, pure hydrocarbons) are not suitable.

· Pipe Material: Non-metallic pipes (e.g., plastic) can weaken the magnetic field, affecting measurement accuracy. For these cases, grounding rings or liners might be needed.

· Minimum Flow Rate: There's a minimum flow rate below which the meter's accuracy can be compromised.

· Installation Requirements: Straight pipe sections are typically required upstream and downstream of the meter for optimal performance.

Applications of Electromagnetic Flow Meters:

· Water and Wastewater Treatment: Monitoring water flow rates, controlling chemical dosing, and effluent measurement.

· Chemical and Process Industries: Measuring flow rates of various chemicals, slurries, and process liquids.

· Food and Beverage Production: Monitoring flow rates of syrups, juices, and other conductive food products.

· Pulp and Paper Industry: Measuring flow rates of pulp slurries and other process liquids.

· Pharmaceutical Manufacturing: Monitoring flow rates of sterile liquids and solutions.

Looking for "Electromagnetic Flow Meter" ?

Explore More Products